Stainless Steel Pipe to Tube Adapters

Stainless Steel Pipe to Tube Adapters

It would be better to begin by clarifying terminology. Most of the time “tube” and “pipe” terms are used interchangeably. Both these terms are described as hollow cylinders made of certain material. The difference between tubes and pipes is that the tubes and tube fittings are specified with exact measurements while in case of pipes the actual dimensions may not be exact.

In addition to that, tubes are used for construction and structural applications whereas pipes are commonly used for liquid, fluid, or gas transportation in industries or in plumbing systems. So, it can be said that pipes are considered suitable for hydraulic and pneumatic applications and tubes are considered suitable for structural and construction applications.

Stainless steel is an alloy that is highly resistant to corrosion, durable, low maintenance, cryogenic toughness, and resistance to high temperatures. The stainless steel pipe-to tube fittings are durable and highly resistant to corrosion because stainless steel contains chromium which when reacts with oxygen creates a thin layer that prevents it from corrosion and rust.

The most commonly used stainless steel pipe-to-tube adapters are:

- Connectors

- Bulkhead

- Elbow

- Tee

- Compression Fittings

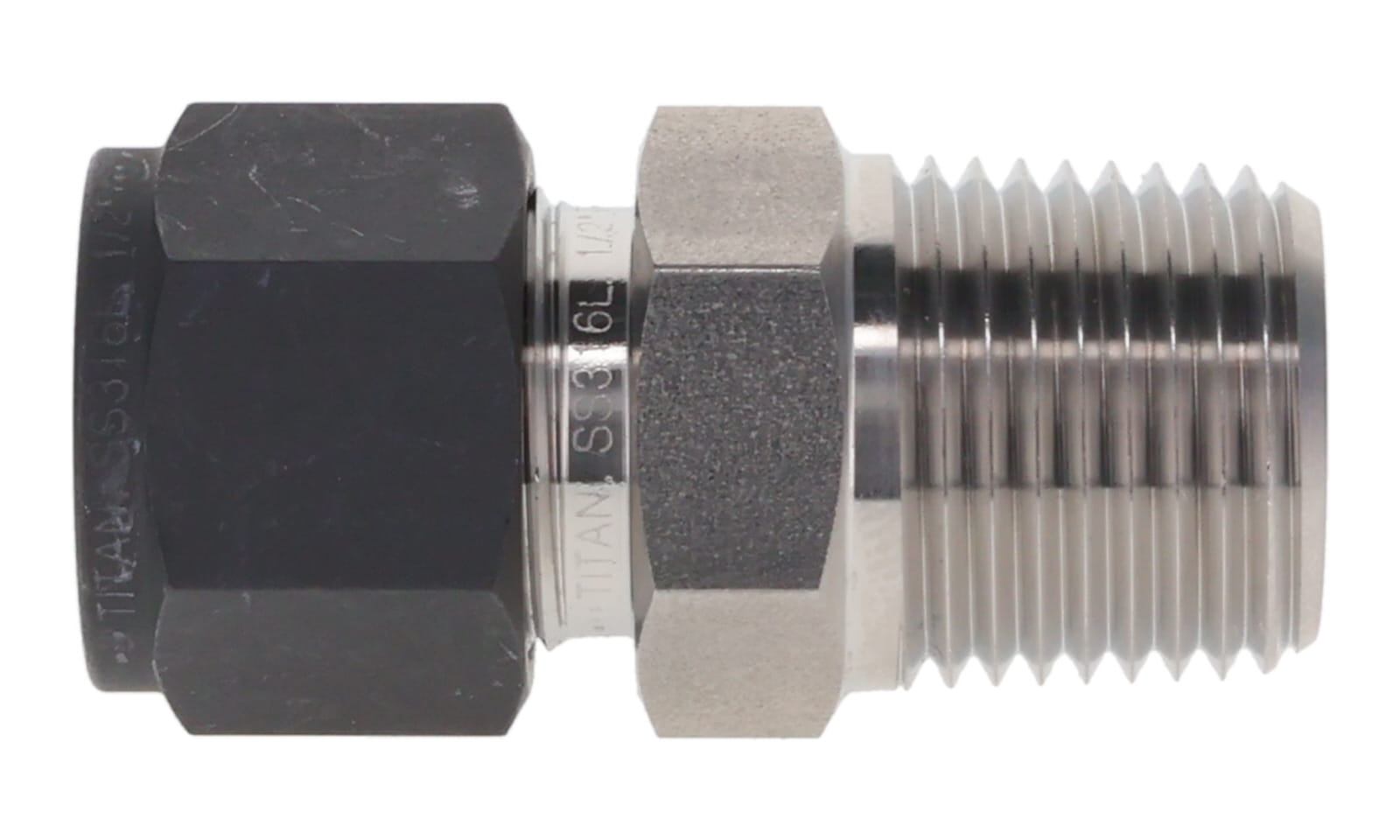

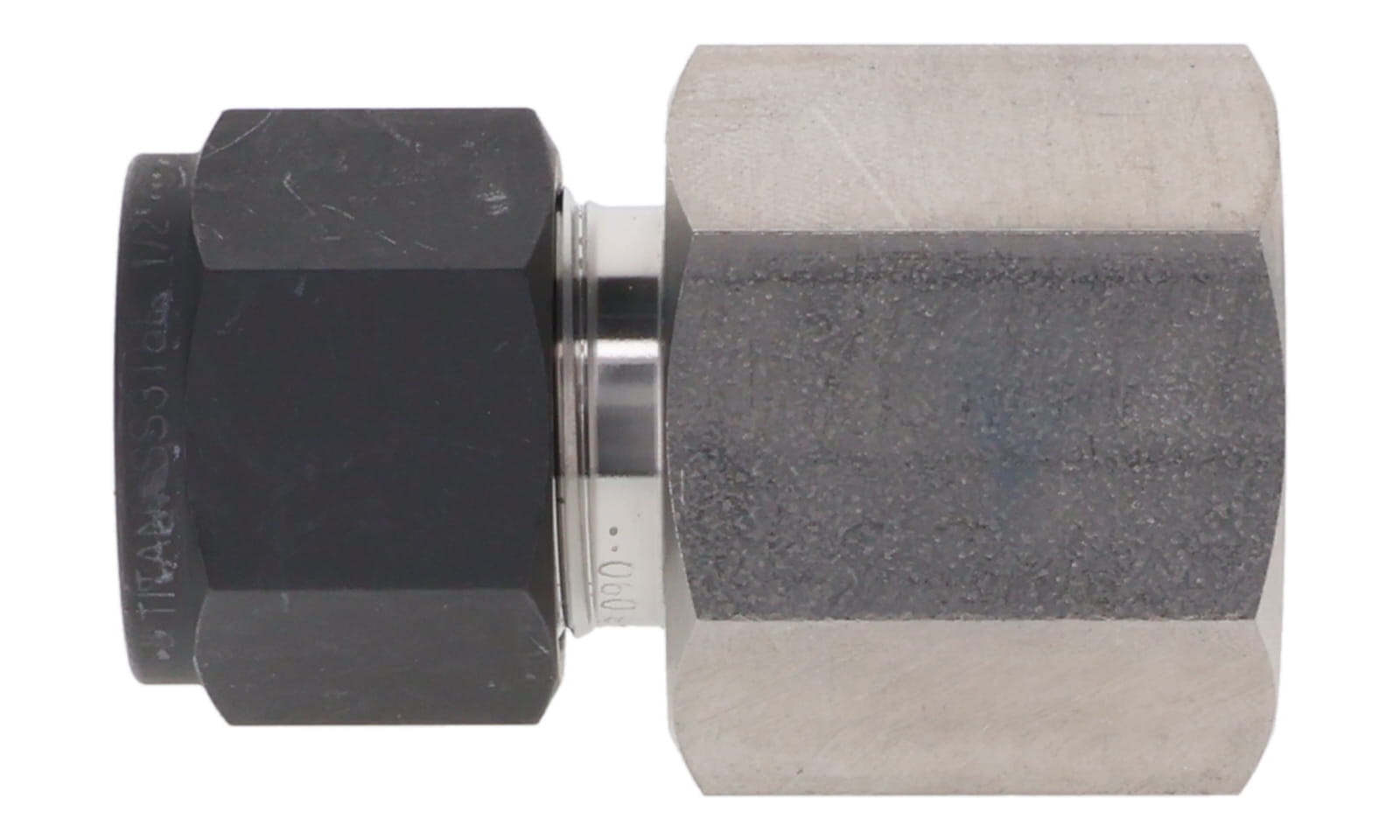

CONNECTORS:

There are two types of tube fittings connectors and unions. The connectors are used to connect pipe threads to a tube and the unions are used to connect to tubes. There are female threaded as well as male threaded connectors known as a female connector and a male connector respectively. The stainless steel connectors are corrosion-resistant, durable, resistant to high temperatures, and ensure high performance even in high-pressure applications. They have cryogenic toughness and are considered reliable and suitable for use in several commercial as well as industrial applications.

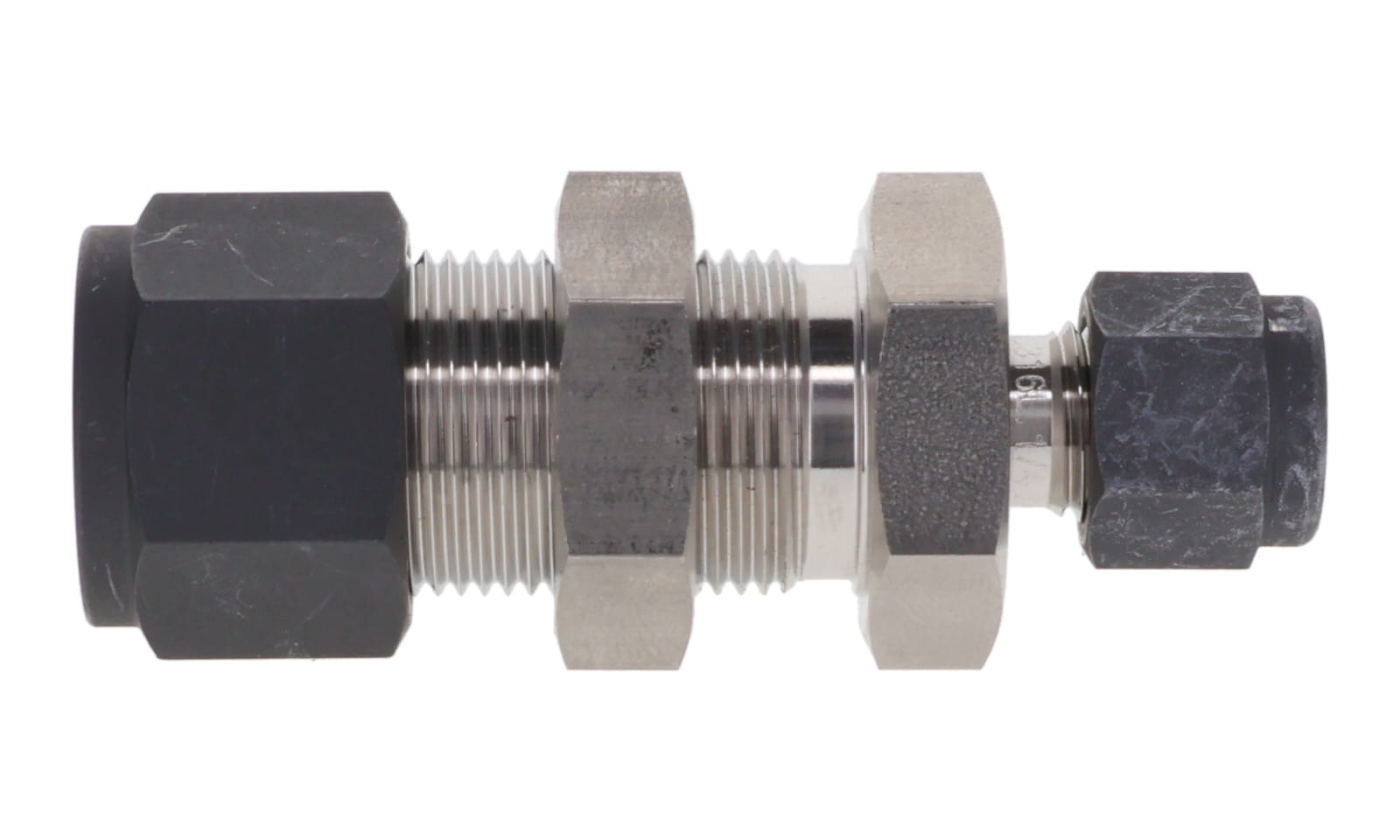

BULKHEAD:

Stainless steel bulkhead pipe-to-tube adaptors are used to allow free flow of liquids or fluids in a vessel, tank, drainage, and similar plumbing connections. The bulkhead fittings are also used as distribution channels in the piping systems. The stainless steel bulkhead fittings are easy to install and have easy adaptation. They are considered suitable for use in high-pressure applications as well as applications where there are high or cryogenic temperatures.

They are available with the male threaded end as well as the female threaded end for connecting to female threaded and male threaded pipes respectively. They may be threaded on both sides too. Some bulkheads may not be threaded at all. The threaded bulkhead fittings are available in two types:

1.Standard Threaded Bulkhead Fittings:

The stainless steel standard bulkhead fittings are male threaded (externally threaded) on both ends and female threaded (internally threaded) on the front end. However, the opposite end is slip fitted.

2. Double Threaded Bulkhead Fittings:

The stainless steel double threaded bulkhead fittings are threaded on all ends whether front or back.

There is another stainless steel bulkhead fitting known as silk bulkhead fitting that has no threads on it and is considered best for adapting an overflow from the side of the vessel or opening in a filter. There are stainless steel double slip bulkhead fittings that are slipped on both from the front as well as the back end. Any PVC pipe can be connected to either end of these stainless steel bulkhead fittings.

ELBOW:

The stainless steel tubing elbows are connectors with a 45° and 90° bent. They are used to change the direction of the flow of liquid, gas, or fluid. The stainless steel elbows are available for male pipe threads as well as female pipe threads.

The stainless steel elbow connectors are reliable, durable, corrosion-resistant, high-temperature resistance, have cryogenic toughness and are considered suitable for use in several commercial as well as industrial applications such as petroleum and refinery, textile, power, and energy supply, paper processing, waste management, water processing and treatment, and chemical processing units.

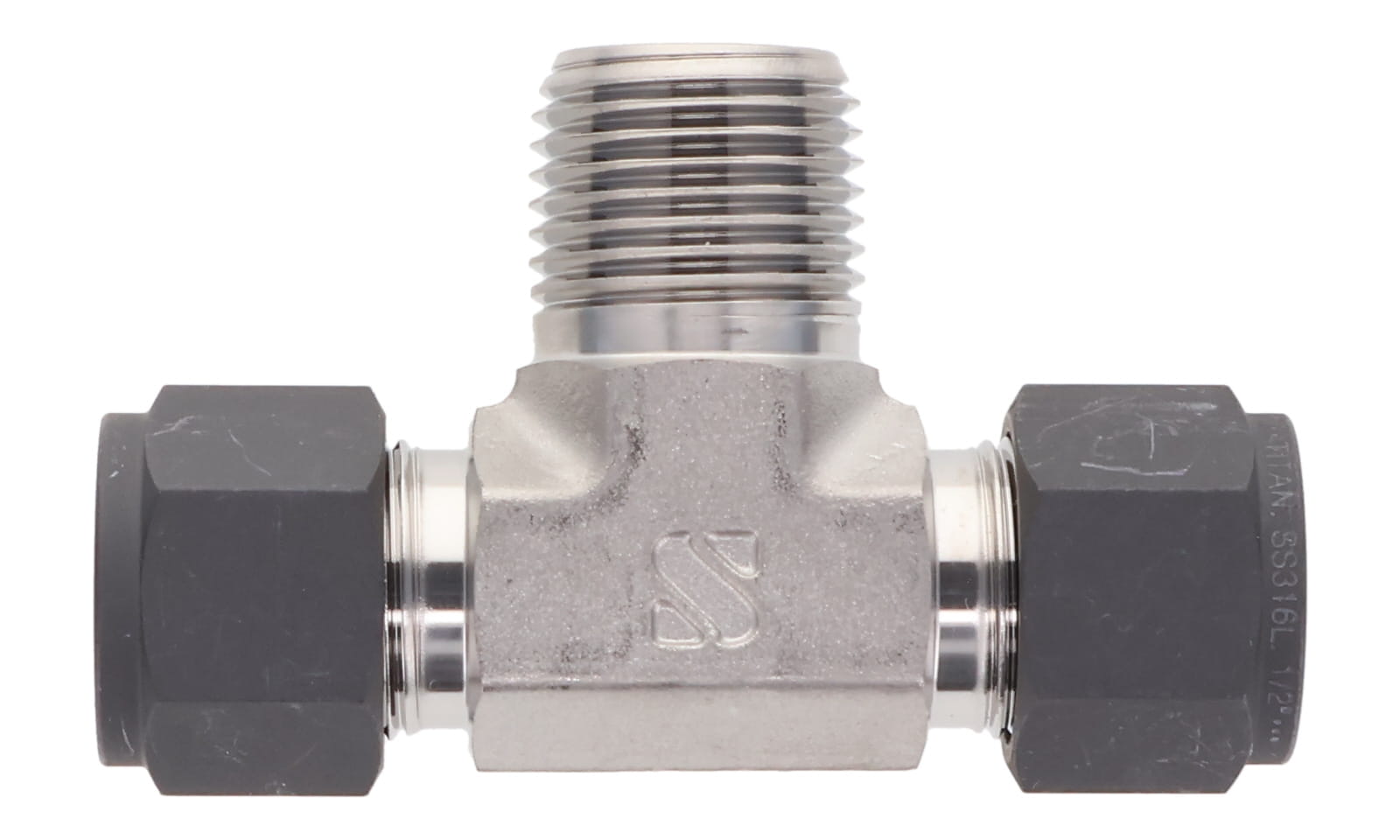

TEE:

The stainless steel tee fittings are corrosion resistant, stronger, and durable. They have three openings; one pipe and two tube end. There are two types of stainless steel pipe-to-tube fittings:

1.The stainless steel tubing male and female-run tee

The male and the female-run tee have its tube ends at an angle of 90° from each other and the pipe end is opposite to one tube end.

2.The stainless steel tubing male and female branch tee

The male and female branch tee have tube ends in a straight line opposite to each other and the pipe end is at an angle of 90° from both tubes ends.

In other words, the main difference between the male and female-run tee and male and female branch tee is the pipe end orientation. In the case of branch tee, the tube ends are in a straight line while in case of run tee the tube ends are at a 90° angle.

The steel tubing tee is used for several applications such as petroleum, chemical processing, refining, paper processing, utilities, and power supply, waste treatment, automotive, textile, gas compression, and marine and industrial equipment, etc.

COMPRESSION FITTINGS:

The stainless steel compression fittings are used to join a piece of tube to a thin-walled pipe or another tube or instrument. The stainless steel compression fitting usually consists of three parts including the body, the nut, and the ferrule but there are compression fittings that contain only two pieces.

The stainless steel compressions fittings are suitable for several commercial as well as industrial applications because they are corrosion resistant and durable. They are used in several applications such as plumbing and electrical systems.