Rust-Resistant Metals in Hydraulics: Exploring Brass and Stainless Steel

Introduction

Ever wondered why brass and stainless steel are the go-to choices for hydraulic applications? It's not just a random preference; there's science and a ton of experience backing this choice. In the world of hydraulics, where precision and durability are king, understanding the materials you work with can make or break your project. This article zeros in on why brass and stainless steel are the stars of the show when it comes to resisting rust.

Brass: The Unsung Hero of Hydraulics

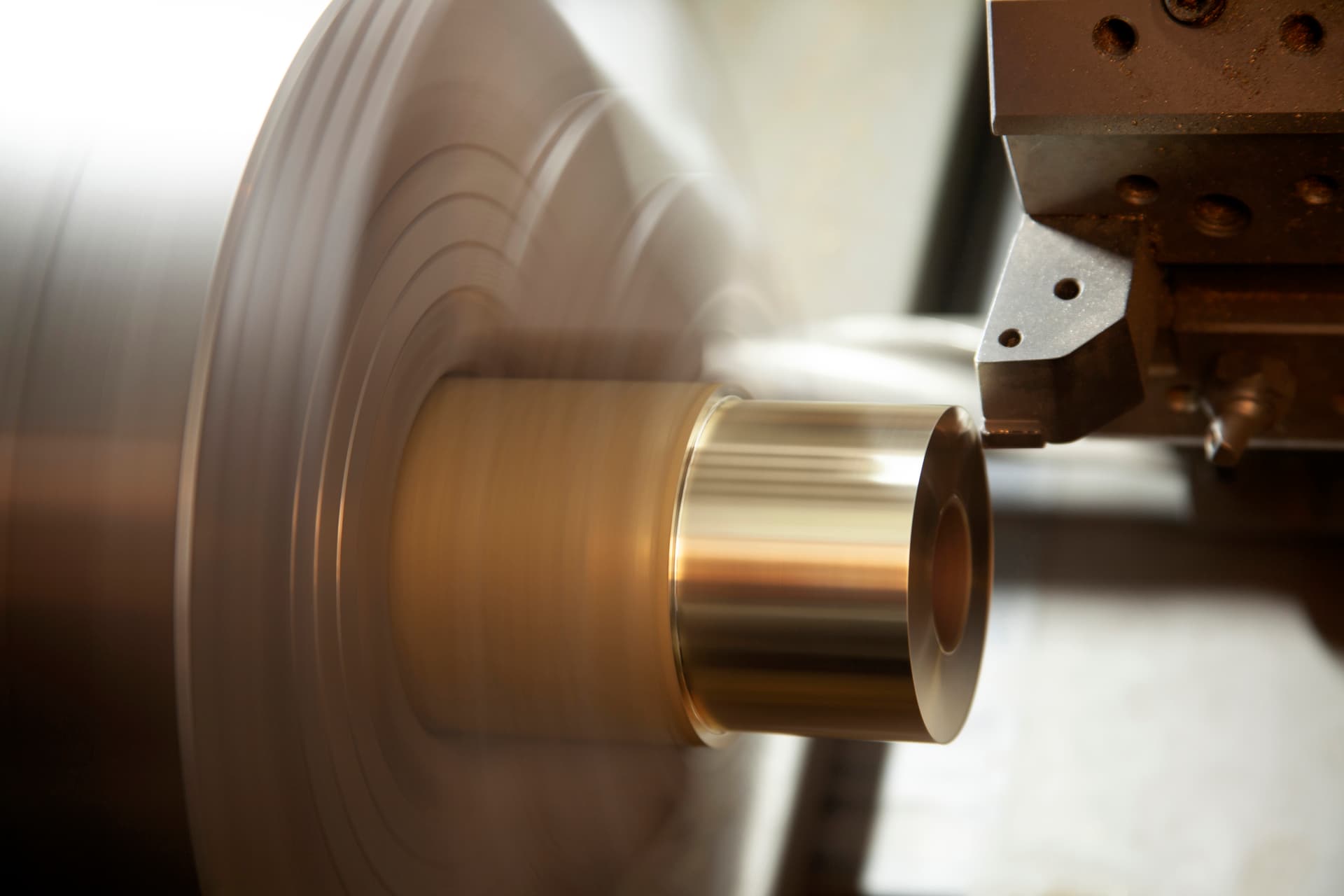

First up, let's talk brass. This alloy, typically a mix of copper and zinc, has been a reliable buddy for hydraulic systems for ages. But what makes it so special? It's all about its resistance to corrosion. Brass doesn't just fight off rust; it's a champion against dezincification - a fancy term for zinc leaching out, which can weaken the metal. This makes brass a top-notch choice for fittings and components that are exposed to water or humid environments.

In the trenches of hydraulic applications, brass fittings are often the silent heroes, offering a combination of ductility and toughness. This means they’re not just rust-resistant; they’re also forgiving under high-pressure scenarios where other materials might crack under the pressure (literally).

Stainless Steel: The Stalwart Defender Against Rust

Moving on to stainless steel – this isn't your average steel. It’s like steel went to the gym and came back bulked up with chromium – at least 10.5%, to be precise. This chromium forms a passive film of chromium oxide, which acts like an invisible shield against rust. Even if the surface is scratched, this film can self-heal, given there’s enough oxygen around.

In hydraulic systems, stainless steel pipes and fittings are practically a staple, especially in situations where corrosion can be a real party pooper. They’re particularly adept at handling both extreme temperatures and varying pH levels, making them ideal for more demanding hydraulic environments.

Practical Applications: Where Each Metal Shines

So, where do you play matchmaker with these metals in hydraulics? Brass finds its groove in environments where there’s a lot of water or steam. Think marine hydraulics or applications involving water-glycol fluids. Its corrosion resistance combined with good thermal conductivity makes it a solid choice.

Stainless steel, on the other hand, struts its stuff in more aggressive environments. We’re talking areas with high chloride content, or where there are harsher chemicals in play. Its ability to stand tall against high temperature and pressure also makes it a favorite for industrial hydraulics.

Choosing Wisely: Tips for the Pros

Alright, when you’re picking between brass and stainless steel, think about your specific application. Consider the environmental conditions, the type of fluid in the system, and the pressure and temperature ranges. Remember, it’s not just about preventing rust; it’s about ensuring the longevity and efficiency of your hydraulic system.

Conclusion

In the ring, brass and stainless steel are heavyweight champions in their own right. Their unparalleled rust-resistant qualities make them indispensable in the hydraulic industry. Whether you’re dealing with the humid conditions perfect for brass or the harsh, high-pressure environments where stainless steel thrives, choosing the right material is critical for the success of your hydraulic systems.

So, next time you’re knee-deep in a hydraulic project, remember the might of these metals. They’re not just preventing a bit of rust; they’re ensuring your systems run smoothly and reliably, day in and day out.

Frequently Asked Questions:

Why is rust resistance so important in hydraulic systems?

Answer: Rust resistance in hydraulic systems is crucial because rust can lead to corrosion, which compromises the integrity and efficiency of the system. Corrosion can cause leaks, blockages, and even system failures, leading to costly downtime and repairs. Rust-resistant metals like brass and stainless steel prevent these issues, ensuring the longevity and reliability of the hydraulic system.

Can brass and stainless steel be used together in the same hydraulic system?

Answer: Yes, brass and stainless steel can be used together in the same hydraulic system, but it’s essential to consider the specific conditions and compatibility. While both metals are rust-resistant, they have different properties and react differently to various environments. It's important to consult with a hydraulic engineer to ensure that using them together won’t lead to issues like galvanic corrosion, which can occur when two dissimilar metals are in electrical contact in a corrosive environment.

Are there any specific environments where stainless steel is preferred over brass in hydraulic systems?

Answer: Stainless steel is often preferred over brass in hydraulic systems that operate in harsher environments. This includes settings with high chloride content, such as seawater or de-icing salts, and situations involving exposure to aggressive chemicals. Stainless steel’s high chromium content gives it a superior ability to resist corrosion in these demanding environments, making it a more suitable choice over brass.