Stainless Steel Pipe to Pipe Adapters

Stainless Steel Pipe to Pipe Adapters

Stainless steel pipe fittings are the components that help in changing the direction of the flow of liquids, gases, or fluids during processing, changing the volume of the flow, or connecting different components of the piping system, controlling the pressure, creating branches or stopping the flow.

There are several different types of pipe fittings and adapters that are used in piping including Tee, Elbow, Reducers, Coupling, Union, Plug and Cap, Bush, Expansion Joints, Nipple, Flanges, and Valves.

Stainless steel has good corrosion resistance and does not rust even with salt water or water at high or low temperatures. The stainless steel is an alloy that has several outstanding characteristics such as durability, lower maintenance, high-temperature resistance, cryogenic toughness, and good corrosion resistance.

The stainless steel pipe to pipe adapters are available in different steel grades including 304, 316, and 316L stainless steel. Different grades of stainless steel are suitable for different environments.

The stainless steel pipe to pipe adaptors are available in several different types for use in different applications such as threaded, flared, without flare and flange adapters. They provide a safe and leak-proof seal for refineries, chemical processing units, power supply units, and different processing lines. They are suitable for high-pressure applications as well as high temperatures, for instance, nuclear industry and petrochemical, etc.

The most commonly used stainless steel pipe to pipe adaptors are:

- Tee

- Elbow

- Reducer

- Cross

- Plug and Cap

- Unions

- Flange

- Nipple

- Valves

STAINLESS STEEL PIPE TEE

The stainless steel pipe tees connect pipes of different diameters and help to change the direction of the flow of water, fluid, liquid, gas, or any material in a pipe. The stainless steel pipe tees are available in various sizes and shapes.

A tee is usually used either to split or combine the flow of the material in the pipe. The different types of tees have different diameters and shapes either branching out or having different angles such as a straight tee or 90° tee, reducing tee, equal tee, wye tee, female, and male branch tee, male and female-run tee and lateral tee. There are several industrial and commercial applications of a stainless steel pipe tee.

STAINLESS STEEL PIPE ELBOW

The stainless steel pipe elbow is installed when connecting a pipe and pipe. It helps in connecting two pipes for changing the direction of the flow of liquid in the pipe. The most commonly used elbow fittings are 45° or 90° elbow.

To control the flow of liquid, gas, or fluid in the pipe reducing pipe elbow is used which has a different size of two sides. Elbows are also classified as Long Radius (LR) Elbows and S Short Radius (SR) Elbows. In LR, the radius is 1.5 times the nominal diameter of the pipe and in SR the radius is 1.0 times the diameter of the pipe. The ends of the stainless steel pipe elbow may be machined for welding, threaded pipe fittings, or socketed.

STAINLESS STEEL PIPE REDUCER

It is used to connect two pipes of different diameters to control the flow. The stainless steel pipe reducers may be in various shapes like tee, elbow, and socket. There are usually two types of reducers depending on the relative positing of the center of the two ends of the reducers; concentric and eccentric reducers. The concentric or conical reducer has the center of both ends on the same axis while the center of both ends in eccentric reducer is not on the same axis.

The stainless steel pipe reducers have good corrosion resistance and are considered suitable for high-pressure applications. It is used to control the volume of the flow of liquid, fluid, or gas in the pipes.

STAINLESS STEEL PIPE CROSS

The stainless steel pipe cross, as the name suggests is shaped like a cross. It has four openings; one inlet and three outlets, or it may be used the other way round. It is suitable for applications in which the main concern is space-saving. The ends of the stainless steel pipe cross are positioned at 90° and there are threads at each end to provide grip and reliable leak-proof seal.

The stainless steel pipe cross is suitable when the thermal expansion is not the concern, for instance, pneumatic systems and fire sprinklers. There are several different types of stainless steel pipe cross including the reducing pipe cross, wing pipe cross, compression pipe cross, and test pipe cross, etc.

The stainless steel pipe cross is used widely in various commercial and industrial applications including chemical processing units, refining, waste treatment, power generation, and gas compression and supply, etc.

STAINLESS STEEL PIPE PLUG and CAP

Stainless steel plug and stainless steel cap are the pipe fittings that are used to seal the openings of pipes when they undergo the process of repair and maintenance. The stainless steel piping plug has male threads and the stainless steel piping cap has a female thread. They have good corrosion resistance and are considered suitable for high-pressure applications.

STAINLESS STEEL PIPE UNION

The fitting used to join two ends of pipes is called union. A union has usually three parts including a nut, a male threaded pipe fitting end, and a female threaded pipe fitting end. The male threaded end and female threaded end is assembled with the help of a nut. It is quite similar to coupling but it is easy to install and remove. There are two types of union fittings ground joint union and flange union. The ground joint union consists of three parts while the flange union consists of two parts only.

STAINLESS STEEL FLANGE ADAPTERS

The stainless steel flange adapters are used to join networks of similar or different materials. Flange adaptors help in connecting flanged parts to the end of a pipe. They are available in anchoring as well as non-anchoring versions. It has broad tolerance which makes it suitable to be used with different types of material. The stainless steel material has good corrosion resistance and makes it good for high-pressure applications.

There are several different types’ flanges such as slip-on flanges, blind flanges, weld neck flanges, and lap joint flanges.

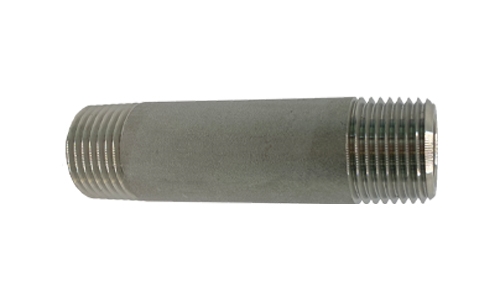

STAINLESS STEEL NIPPLE

The stainless steel pipe nipple is a fitting that has male threaded pipe fitting ends for the purpose of connecting two female threaded pipes. They are usually considered suitable for use in low-pressure applications. The stainless steel pipe nipples are cut in a specific length; it is manufactured in seamless as well as welded form. There are several types of stainless steel pipe nipples such as hexagonal nipple, reducing nipple, welding nipple, hose nipple, and close or running nipple.

The stainless steel nipple ends are of different types. They may have one plain end or both ends plain, one threaded pipe fitting end or both threaded pipe fitting ends, one beveled end or both beveled ends, or combination of the above.

- Stainless steel pipe nipple having both plain ends is usually used for a socket weld connection.

- Stainless steel threaded pipe nipple usually has male threaded pipe fitting ends that are used for female threaded connections.

- Stainless steel pipe nipple having beveled ends is used for creating welded connections.

STAINLESS STEEL VALVES

Stainless steel pipe valves are one of the important pipe fittings. It is a fitting that is used to control the flow of liquid, fluid, or gas either by opening or closing the passageways completely or partially.

The most ancient valve is a non-return valve that ensures that liquid flows in one direction only. The modern-day valves have now additional functions such as regulating the flow and volume and controlling the pressure which is commonly known as a throttling valve. There are valves that are used to isolate a particular section of the piping system in order to repair or replace certain fittings in the piping system which is known as the isolation valve.

There are several different kinds of valves such as ball valves, check valves, butterfly valves, air release valves, needle valves, gate valve, globe valve, plug valve, foot valve, blowdown valve, pinch valve, pressure reducing valve and pressure-relieving valve.

The stainless steel pipe valves are connected to the pipes or piping systems by using different compression fittings, flanges, and welding, etc.

The stainless steel pipe valves have good corrosion resistance and are considered suitable for high-pressure applications. They are used for several different commercial and industrial applications.